OEM Factory for Sintered Stone Chamfer Polishing Machine - CGSC641 Stone Edging Machine – SUNKON

OEM Factory for Sintered Stone Chamfer Polishing Machine - CGSC641 Stone Edging Machine – SUNKON

OEM Factory for Sintered Stone Chamfer Polishing Machine - CGSC641 Stone Edging Machine – SUNKON Detail:

DESCRIPTION

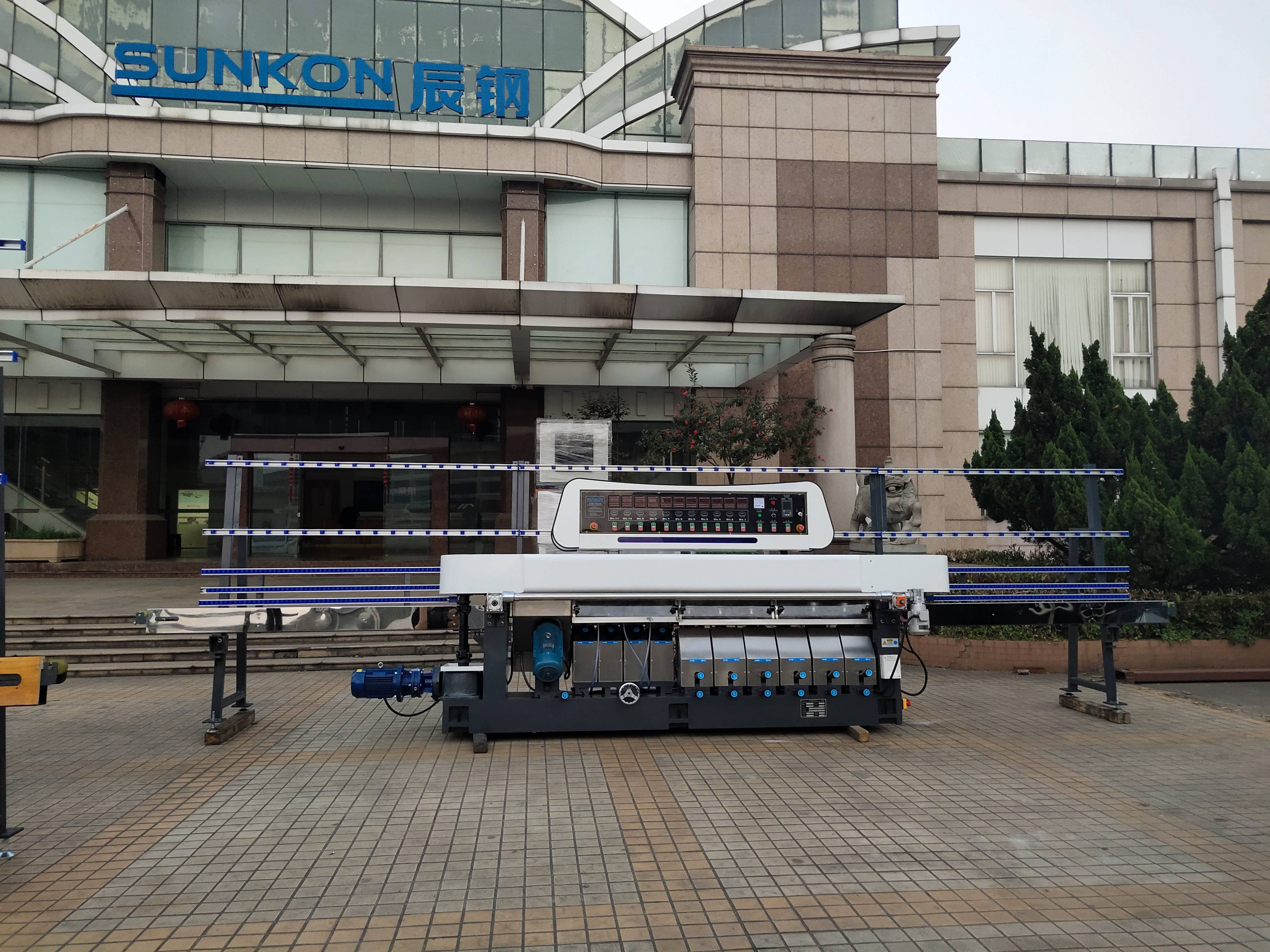

■CGSC11 It’s suitable for processing various size and thickness of all kinds of stone, marble and granite. It equips with diamond wheel, water abrasive discs, polish cotton discs, connecting snail lock to process 45 degree angle, flat edge, thicken bottom edge, skirting line etc.

■Coarse grinding, fine grinding, polishing and chamfering can be completed in one-time processing.

■The base, front and rear beams, beds and grinding heads are of casting materials (annealed to prevent deformation), Which can bear large loads and has stable performance.

■Spindle base structure is with new design, made of 20mm thick steel panel, stable and indeformable, make sure motor without vibration even when processing thick and big stone piece.

■ Machine capacity equals to workload of 15 men in normal processing, what’s more, machine processing avoids artificial effect well.

■ It is the best stone grinding equipment for batch production in stone processing industry.

TECHNICAL DATA

|

NAME |

DATE |

| Max.Glass size | 2500×2500mm |

| Min.Glass size | 100×100mm |

| Glass thickness | 3-30mm |

| Transmissinon speed | 0.5-6m/min |

| Bevel angle | 0~25° |

| Max.hemline grinding | 3mm |

| Max. arris grinding | 2.5mm |

| Power | 19.5KW |

| Weight | 2800kg |

| Land occupation | 7000×1000×2500mm |

WHEELS PLACEMENT

|

NO |

Motor |

Power (KW) |

GRINDING WHEEL |

|

name |

|||

|

1 |

profile rough |

4.5 |

Diamond wheel |

|

2 |

profile rough |

4.5 |

Diamond wheel |

|

3 |

Polishing |

3 | Water abrasive plate |

|

4 |

Polishing |

3 |

Water abrasive plate |

|

5 |

Polishing |

3 | Water abrasive plate |

|

6 |

Polishing |

3 | Water abrasive plate |

|

7 |

profile rough |

3 | Diamond wheel |

|

8 |

Polishing |

3 | Water abrasive plate |

|

9 |

Polishing |

3 | Water abrasive plate |

|

10 |

Polishing |

3 | Water abrasive plate |

|

11 |

front chamfer cutting |

5.5 |

blade |

MAIN STRUCTURE PARTS

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for OEM Factory for Sintered Stone Chamfer Polishing Machine - CGSC641 Stone Edging Machine – SUNKON , The product will supply to all over the world, such as: United Kingdom, Mumbai, Liberia, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.