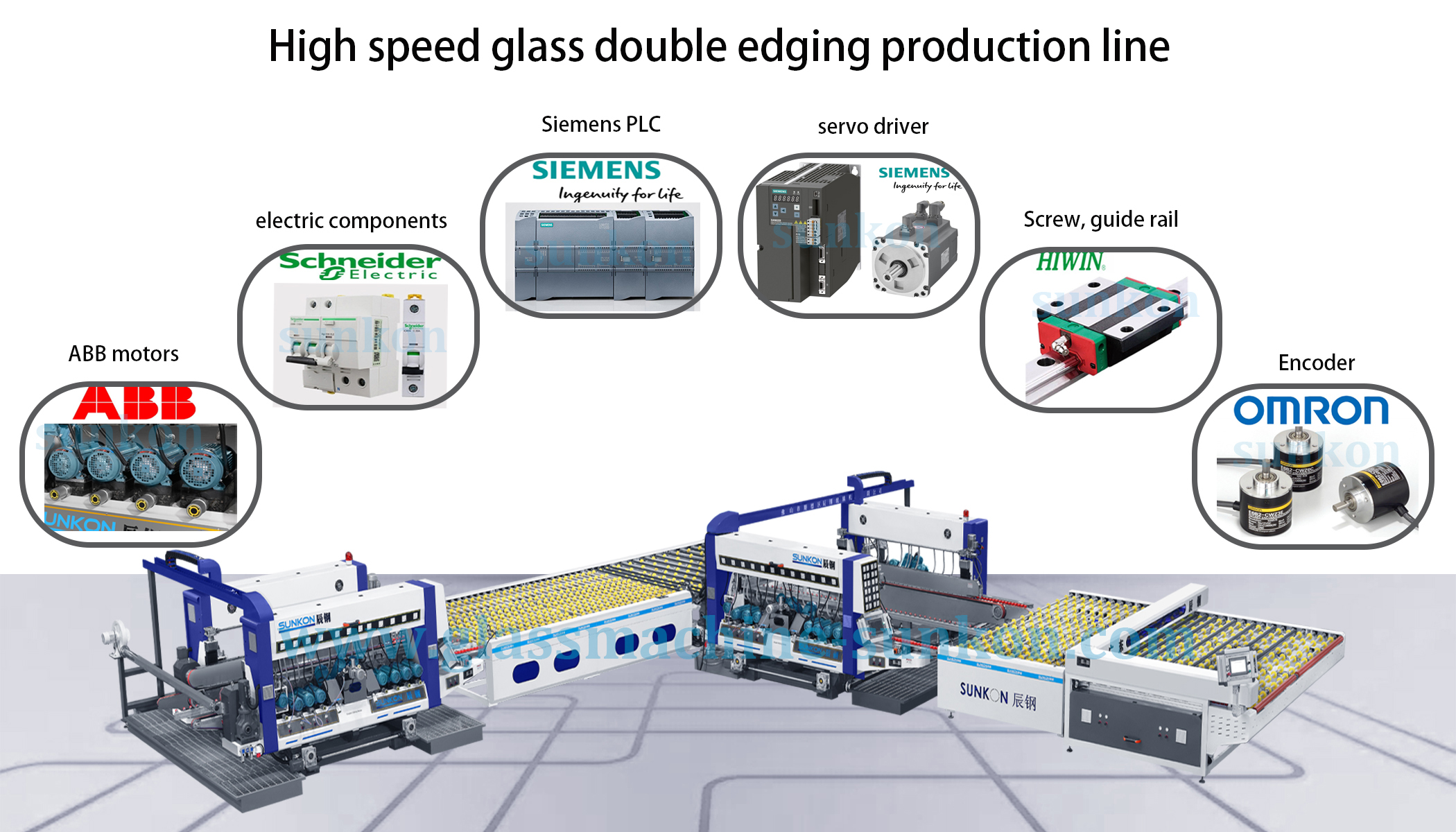

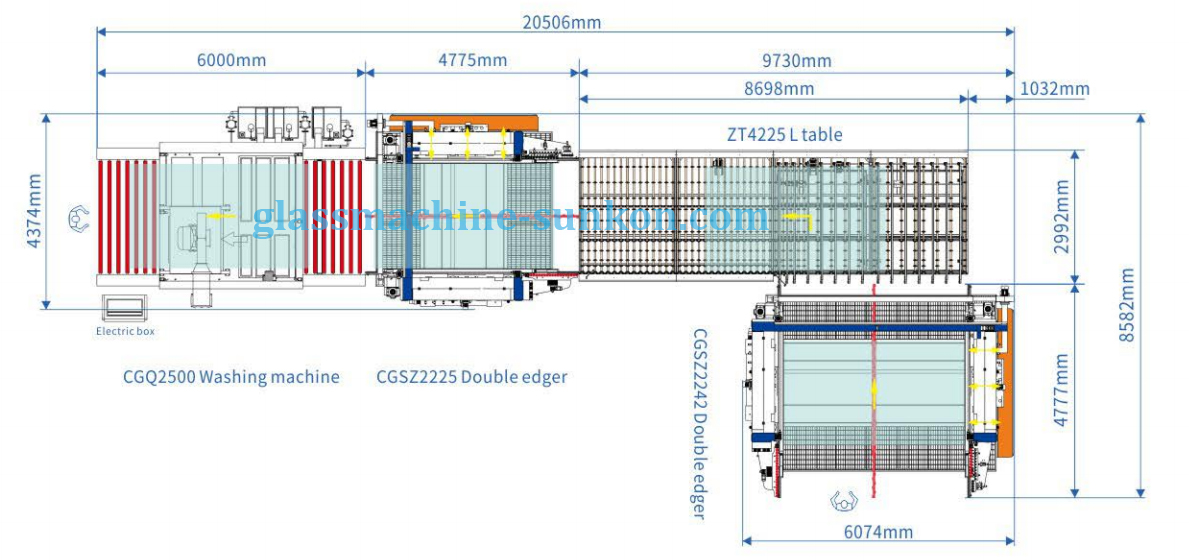

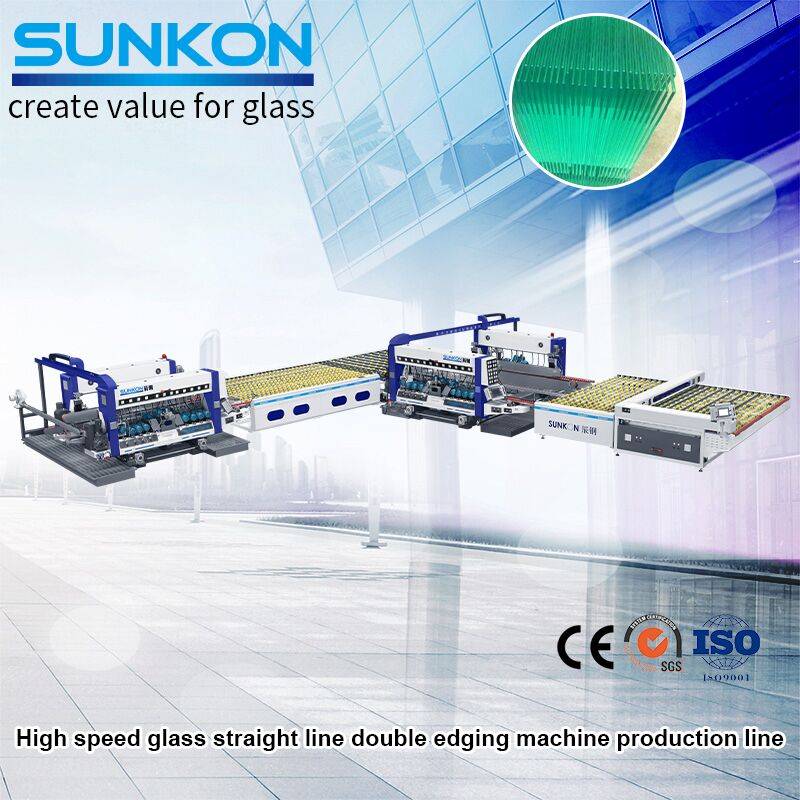

100% Original Glass Cutting Machine - CGSZ4225-24 High Speed Glass Straight Line Double Edging Machine Production Line(L type) – SUNKON

100% Original Glass Cutting Machine - CGSZ4225-24 High Speed Glass Straight Line Double Edging Machine Production Line(L type) – SUNKON

100% Original Glass Cutting Machine - CGSZ4225-24 High Speed Glass Straight Line Double Edging Machine Production Line(L type) – SUNKON Detail:

VIDEO

DESCRIPTION

APPLICATION

Construction Glass

Industrial Glass

Door and window Glass

Furniture Glass

Appliance Glass

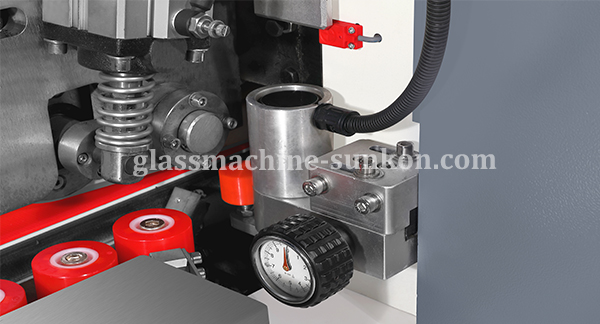

WHEELS PLACEMENT

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Glass Thickness | 3-25mm |

| Min Processed Size | 350*350mm |

| Max Processed Size | 4200mm(CGSZ4225) |

| Process Speed | 1-15m/min |

| Working Height | 920mm |

| Total Power | 47kw |

MAIN STRUCTURE PARTS

01 Reasonable Layout of wheels

Adopt famous motor brand “ABB” , and reasonable layout of wheels to make good performance on glass edge. The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing

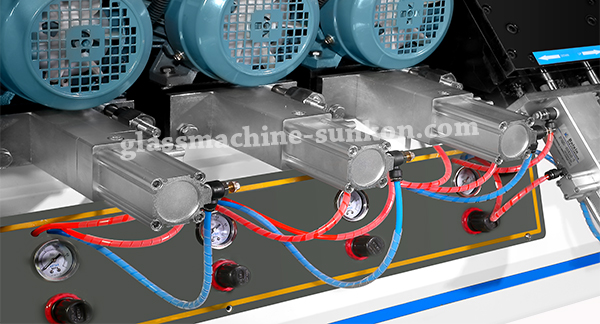

03 Pneumatic polishing

All polishing wheels adopt pneumatic polishing, and the polishing head is in and out pneumatically at the same time, equipped with high-precision motor carriage, the polishing effect is guaranteed

04 Open-close control for glass processing width

Siemens servo motor adjusts the opening and closing of the machine to make sure smooth running even in high speed.

05 Extra cutting quantity detect device

When the extra edge of coming glass touches this device, it will pass signal to PLC and the machine will be informed to slow down for this extra edge. Then the glass grinding and polishing quality will be much better.

06 Side pressure correction device

Input structure is with side pressure correction device, which is easy for adjusting and maintenance.

CUSTOMER CASE

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for 100% Original Glass Cutting Machine - CGSZ4225-24 High Speed Glass Straight Line Double Edging Machine Production Line(L type) – SUNKON , The product will supply to all over the world, such as: Macedonia, Georgia, Swedish, We are looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products' quality, you can return within 7days with their original states.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

.jpg)