CGSZ2225 22 Motors Glass Double Edging Machine

CGSZ2225 22 Motors Glass Double Edging Machine

DESCRIPTION

■The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing.

■All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation. The main body adopts cast iron with annealing treatment.

■Installed with excellent linear guide and screw mandrels which ensures the processing precision. Bracket of movable side system is W frame design, which increases the accuracy of movements and the degree of stability; also it can extend the life time of the linear rack

■Position corrected device has been added on the machine, which solves the deviate problem of small glass, and truly realize intelligent operation of connected machines when transferring glass.

■PLC control with touch screen, the data setting and the grinding status of glass can show on the controlling center. Processing width, thickness, and lifting of upper arris are adjusted automatically.

■The improved pneumatic polishing uses the high precision linear guide rail for guiding and this structure can make polishing more stable and reliable, as well as to save the grinding wheel effectively.

APPLICATION

Construction Glass

Industrial Glass

Door and window Glass

Furniture Glass

Appliance Glass

WHEELS PLACEMENT

| Glass Thickness | 3-25mm |

| Min Processed Size | 350*350mm |

| Max Processed Size | 2500*2500mm |

| Process Speed | 1-12m/min |

| Working Height | 920mm |

| Total Power | 58kw |

MAIN STRUCTURE PARTS

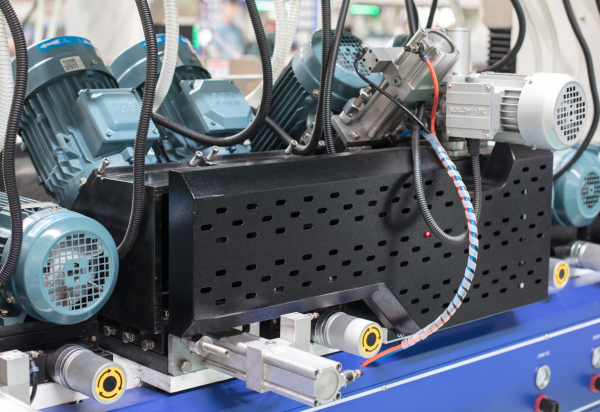

01 Reasonable Layout of wheels

Adopt famous motor brand “ABB” , and reasonable layout of wheels to make good performance on glass edge. The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing

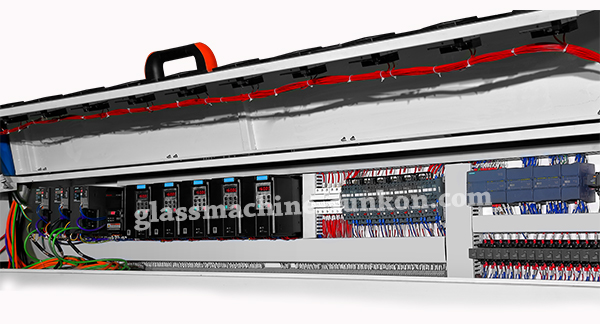

02 Tidy circuit box

Adopts Schneider electrical components and Siemens PLC. All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation.

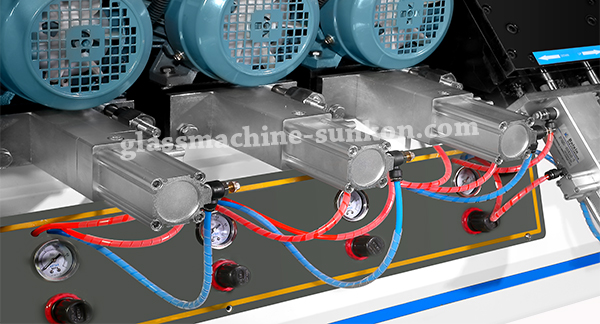

03 Pneumatic polishing

All polishing wheels adopt pneumatic polishing, and the polishing head is in and out pneumatically at the same time, equipped with high-precision motor carriage, the polishing effect is guaranteed

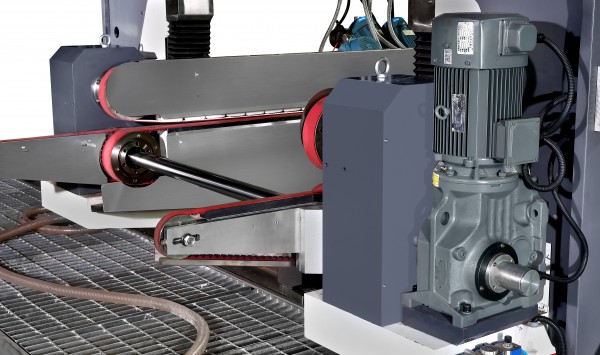

04 Variable frequency drive system

Screw drive, two large gears ensure strong conveying. The transmission synchronization is higher and the precision is more accurate.

05 Chamfer structure

The chamfer adopts a secondary transmission structure, and the chamfer motor is placed on the upper side at an angle of 45°, which greatly avoids the phenomenon that the traditional chamfer motor is placed down at 45° and caused the motor to be burned out by water.

06 Side pressure correction device

Input structure is with side pressure correction device, which is easy for adjusting and maintenance.

CUSTOMER CASE